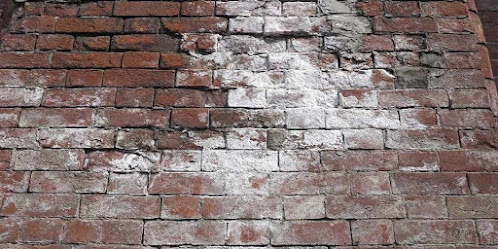

The

Word ‘Efflorescence’ is used to describe the depositing of

soluble salts (in other words, those that dissolve in water) on the surface of

finished brickwork. Salts of magnesium, calcium, potassium or sodium may have

been present in the clay used to make the bricks or in the sand used to make

the mortar.

What are the Sources of Soluble Salts?

The sources of soluble

salts Common efflorescence derives mainly from soluble salts that are contained

in clay bricks and sands used for mortars but sometimes in other sources,

including ground water.

Clay

Impurities in clay raw

material from which bricks are made, include various soluble salts. These salts

are impossible to remove before bricks are made, and can cause problems of

efflorescence and sulphate attack on cement mortar in walls which may be wet

for long periods each year in completed buildings.

Mortar sands

Most sands come from

pits or river beds, and contain few salts. Sea sands contain many harmful

salts, however, and should not be used for mortars unless they have been

effectively washed by a reliable supplier.

Cement

Portland cement is the

main binder constituent used, and its contribution to efflorescence is minimal.

Mainly due to the desire to reduce carbon emission from cement production,

alternative binders are used in modern cements and they can contain appreciable

quantities of sodium sulfate, which is a common cause of efflorescence

Detergents used as plasticisers

Many detergents

contain sodium sulfates and should under no circumstances be used in place of

properly formulated proprietary mortar plasticisers (see Section 3.1).

Other sources

Bricks may absorb

salts from ashes or the soil on which they are standing or from materials

stacked or heaped in contact with them.

How efflorescence in brickwork forms?

Water dissolves

soluble salts in the bricks or mortar and holds them in solution.

As the water

evaporates and the wall dries out, the solution becomes more concentrated until

salts begin to be deposited.

This may occur out of

sight within the pores of the brick or on the surface.

Exactly where, when

and how much efflorescence will occur is difficult to predict. Because it

dependent on complex chemical and physical conditions such as the type of

salts, the pore structure within the brick, the rate of drying by wind and sun,

and the degree of saturation of the brickwork. The latter is the only condition

which we can readily control.

How to minimize the risk of efflorescence in brickwork?

The risk cannot be

entirely avoided, as it is not practicable to eliminate all salts from bricks

and mortars, or to keep them virtually dry, but it can be minimised by reducing

the amount of water penetrating the brickwork.

Design details

Designers can use

‘umbrella’ details which protect the brickwork from saturation. Such details

include effective roof verges and eaves, copings and sills to shed run-off

water clear of the brickwork below.

They should also avoid

details which shed water onto projecting plinths and other features.

Site practice

·

Bricklayers and site

supervisors are responsible for good site practice.

·

Bricks should be

stacked clear of the ground on pallets, or by other means.

·

Mortar materials

should be kept free from contamination.

·

Bricks in stacks or on

the scaffolding, and newly built brickwork, should be protected from

saturation, particularly during the seven days after bricklaying.

·

Scaffold boards

adjacent to the brickwork should be turned back during rain to avoid splashing

causing a band of efflorescence as well as mortar stains.

Choice of bricks

New bricks are tested

by manufacturers for the extent to which they are likely to effloresce and

bricks are graded on the following scales in terms of the bricks’ exposed

surface area:

·

Nil

: no perceptible

efflorescence.

·

Slight

: no more than 10

per cent displays a thin covering.

·

Moderate

: thin covering

affecting between 10 and 50 per cent.

·

Heavy

: heavy deposits

affecting more than 50 per cent but with no flaking.

·

Serious

: heavy deposits

displaying surface powdering/ flaking, which increases during wet weather.

Before finalizing

sources of brick for procurement, always do sampling of brick and

test it for efflorescence as per IS code. If it passes the test, then go for

procurement.

Efflorescence can be

avoided, or at least minimised, by appropriate design detail and good site

practices.

How to Treatment Surface Affected by Efflorescence?

The only real solution

to efflorescence is periodically to brush off the salt deposits from dry

brickwork as they come to the surface until, over time, all the salts have been

released.

Always use a bristle

brush and never a wire brush.

It is a mistake to try

to wash off the efflorescence as this will merely re-dissolve the salts and

wash them back into the brickwork, ready to emerge again when the brickwork

dries out.

Do not use acid

treatment, as apart from the danger to people and materials by inexpert use,

some salts such as vanadium (a trace metallic compound associated mainly with

fireclays) may be fixed permanently.

Internal efflorescence

may be treated by dissolving small patches with very little water, say a fine

mist spray. The surface may then be dried with a damp sponge but, because some

users have reported that this sometimes causes a blotchy appearance, it is

advisable to experiment on a small inconspicuous surface at first. The

absorbent material must be constantly renewed or washed free of salts.

No comments:

Post a Comment